Tool Management & Tool Data Management

Download tool data directly from the manufacturer’s tool catalog!

Smooth integration to all common CAM systems & NC simulation

Smooth integration to all common CAM systems & NC simulation

Organization & management of tools & NC programs

Organization & management of tools & NC programs

Overview of tool locations at all times with RFID

Overview of tool locations at all times with RFID

Direct communication with the cnc controller

Direct communication with the cnc controller

Comparison of actual values in simulation & production

Comparison of actual values in simulation & production

More than 949,000 cutting tools

40 tool manufacturers in comprehensive search

Characteristics according to DIN 4000/ISO 13399

Digital twin according to DIN 4003

Full integration with popular CAM systems

More than 25 years of experience with tools and tool data

You save time and costs, avoid risky input errors and sustainably secure knowledge in the company.

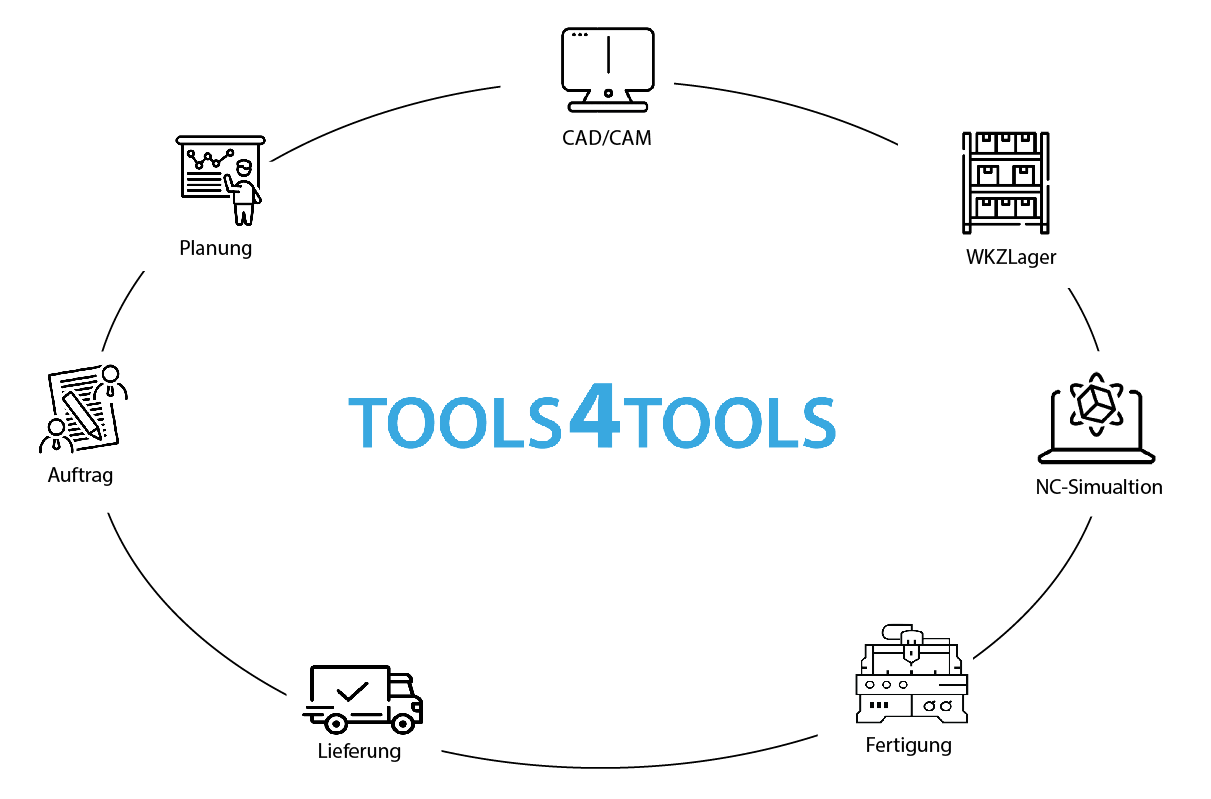

Tools4Tools is the professional and universal interface software to exchange tool data between the different participants of the manufacturing process.

Tool lengths and diameters are made available to the programming and the machines by the tool setting device.

Tool lists are read from controllers for CAD/CAM programming.

These participants perform a wide variety of tasks. Geometry and cutting data from the manufacturers are loaded from the cloud and sent to the CAD/CAM system.

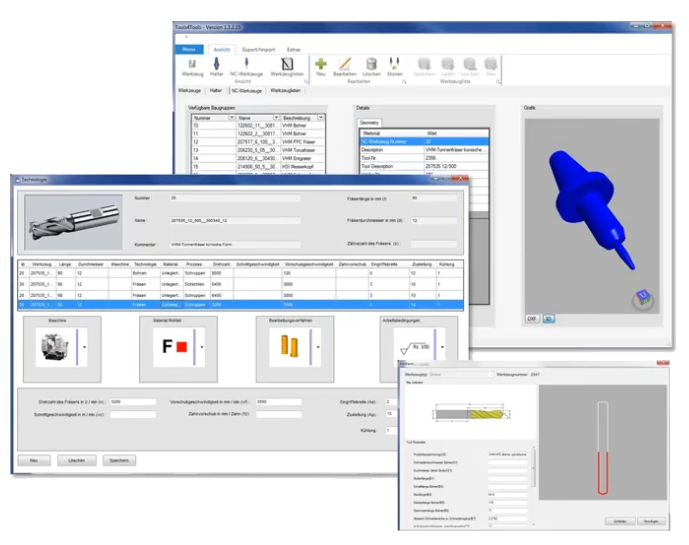

Parametric tool view

Parametric tool view

3D display of complete tools

3D display of complete tools

Multiple technology sets per tool

Multiple technology sets per tool

Revision of the technology classification

Revision of the technology classification

USB interface file transponder

USB interface file transponder

Simplified tool input window

Simplified tool input window

R F I D T O O L I D E N T I F I C A T I O N

The identification of tools by RFID tags provides a better and digitized overview of the tool data available in the plant.

With Tools4Tools, the storage locations of the tools can thus be located in no time at all.

Very easy and fast reading of the tools by RFID into the Tools4Tools tool management.

Continuous control of where and in what condition the tools are.

Optimization of the entire tool data stock and correct allocation.

Uncomplicated, fast digitizing of tools from stock.

A D V A N T A G E S O F D I G I T A L I Z A T I O N

Keep everything under control!

1. Order

2. Planning

3. CAD/CAM – Tools from Tools4Tools Download & Import

4. Tool storage – All tools available? Where?

5. NC Code Simulation – Nc program verification / collision check

6. Manufacturing – Machine loaded with correct tools?

7. Delivery – On time!

By digitizing the process chain, especially the tools, you have an overview of ALL data in Tools4Tools..

The tools, which are equipped with our RFID chips, can be located at any time via Tool4Tools. This means you always know where the tools you need for production are, whether they are currently in use and where they are stored.